Tel/WhatsAapp:+86 13366396425

E-mail: chloe_xia@vleap.com.cn

Every bag starts as a fabric decision.

Before you choose size, style or printing, you’re really deciding:

The Custom Bag Fabric system at FYBagCustom is designed to answer those questions from a B2B, engineering-first perspective.

As a custom bag manufacturer in China, we don’t only ask “nylon or canvas?”

We ask what your customer needs, then match that with:

These fabrics become the foundation for all your other customizations: bag type, size, style, pattern, printing method, design features and special craftsmanship.

You can engineer straps and seams perfectly, but if the base fabric is weak, the bag will still fail early.

Fabric directly determines:

For example, densely woven nylon and polyester fabrics are widely used in backpacks and travel bags because they combine good strength with relatively low weight and can be coated for water resistance.

The same silhouette in different fabrics can look like:

Your fabric system needs to match your Custom Bag Style: minimalist, functional, fashion, boho, handmade, etc.

Fabric choices define:

For B2B brands, the right custom bag fabric strategy balances:

Nylon fabrics are common in:

Why B2B brands choose nylon:

We typically define nylon by:

For a custom nylon bag, we match:

Polyester is widely used in:

Why B2B brands choose polyester:

For custom polyester bags, we adjust:

Polyester is often the base for:

Canvas fabrics are common in:

Why B2B brands choose canvas:

We typically define canvas by:

For a custom canvas bag, we match:

Cotton fabrics are common in:

Why B2B brands choose cotton:

We define cotton by:

For a custom cotton bag, we match:

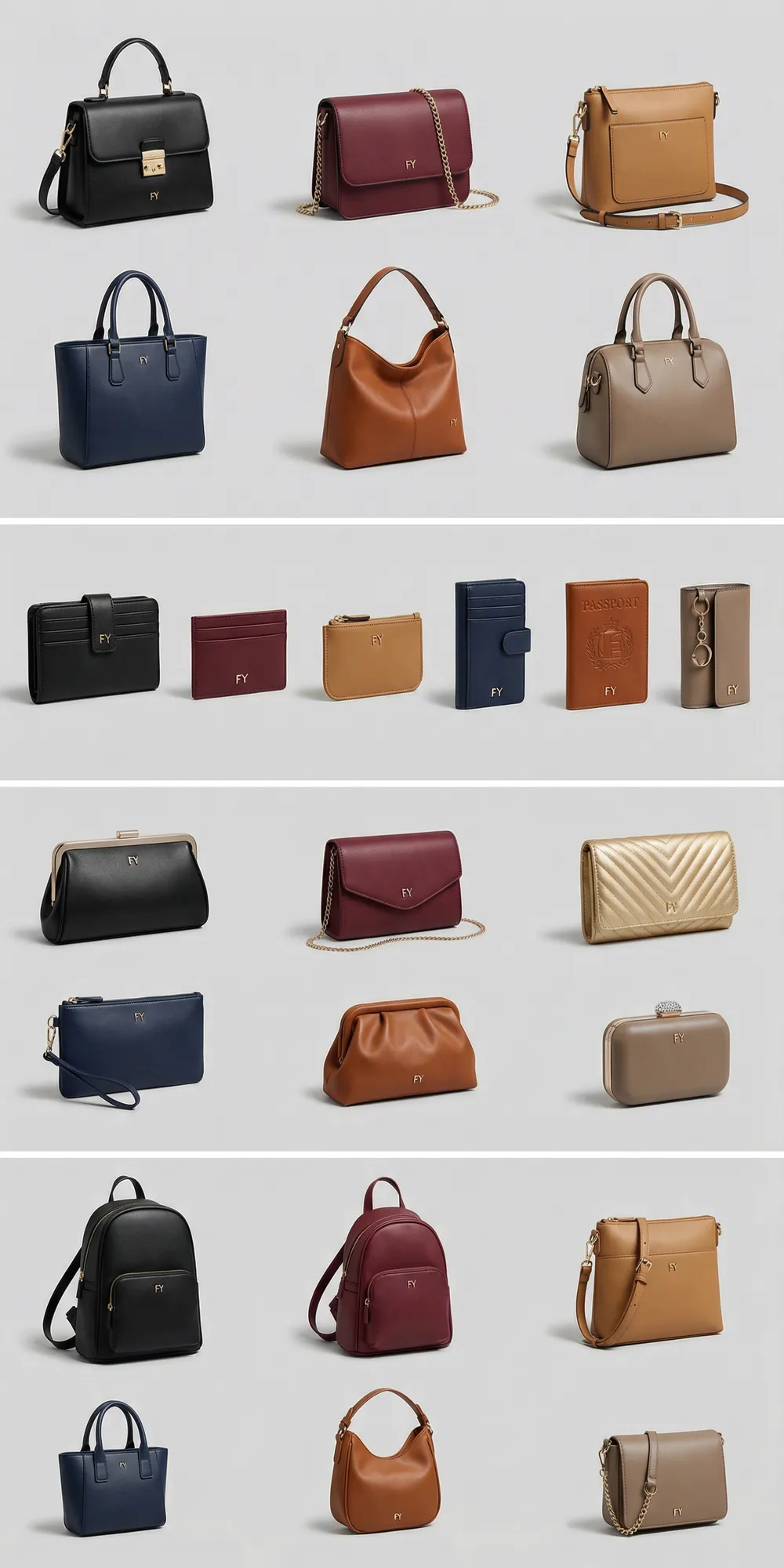

Leather and PU (synthetic leather) are key in:

Why B2B brands choose leather/PU:

For a custom leather bag, we consider:

For PU (synthetic leather):

We engineer linings, reinforcements and edge structures to support:

Neoprene (or neoprene-style) fabrics are common in:

Why B2B brands choose neoprene:

We define neoprene systems by:

For a custom neoprene bag, we match:

Straw, raffia and similar woven fibres are perfect for:

Why B2B brands choose these:

We consider straw systems in terms of:

For a custom straw bag, we match:

Non-woven fabrics are common in:

Why B2B brands choose non-woven:

We categorize non-wovens by:

For a custom non-woven bag, we match:

Tyvek-type materials are common in:

Why B2B brands choose Tyvek-style fabrics:

We look at Tyvek-like materials in terms of:

For a custom Tyvek bag, we match:

PVC and clear PVC are common in:

Why B2B brands choose PVC / clear PVC:

We define PVC systems by:

For a custom PVC bag, we match:

Jute and burlap are common in:

Why B2B brands choose jute/burlap:

We approach jute/burlap by:

For a custom jute bag, we match:

Eco-friendly and recycled fabrics are increasingly used in:

Why B2B brands choose eco fabrics:

We work with:

For a custom eco-friendly bag, we match:

Tell us your bag types, target customers and desired brand image.

We’ll build a custom bag fabric roadmap and material system that supports your current collection—and your future growth.

You tell us:

We propose:

We:

When final fabrics are chosen:

| Fabric | Water Resistance | Weight | Texture | Printability | Sustainability | Typical Bags |

|---|---|---|---|---|---|---|

| Nylon | ★★★★☆ | Light | Smooth | Moderate | ★★☆☆☆ | Backpack / Duffle |

| Polyester | ★★★★☆ | Light | Semi-smooth | ★★★★★ | ★★★☆☆ | Tote / Storage |

| Canvas | ★★★☆☆ | Medium | Textured | ★★★★☆ | ★★★★☆ | Tote / Storage |

| Cotton | ★★☆☆☆ | Medium | Soft | ★★★☆☆ | ★★★★★ | Makeup / Lunch |

| Leather | ★★★★★ | Heavy | Luxurious | Laser / Emboss | ★★☆☆☆ | Handbag / Wallet |

| Neoprene | ★★★★☆ | Medium | Elastic | ★★★☆☆ | ★★★☆☆ | Laptop / Sports |

| Tyvek | ★★★★☆ | Ultra Light | Paper-like | ★★★★☆ | ★★★★★ | Eco Tote / Travel |

| PVC | ★★★★★ | Medium | Glossy | ★★★★☆ | ★★☆☆☆ | Cosmetic / Clear |

| Jute | ★★☆☆☆ | Medium | Coarse | ★★☆☆☆ | ★★★★★ | Beach / Gift |

| Straw | ★★☆☆☆ | Light | Braided | Limited | ★★★★☆ | Resort / Boho |

| Non-Woven | ★★☆☆☆ | Ultra Light | Flat | ★★★☆☆ | ★★★★☆ | Promo / Packaging |

| RPET / Eco | ★★★★☆ | Light | Variable | ★★★★☆ | ★★★★★ | Sustainable Lines |

| Material | Key Advantages | Best-Fit Bag Types | Sustainability & Compliance Notes |

|---|---|---|---|

| Cotton Canvas (10–20 oz) | Breathable, sturdy, natural texture, supports detailed screen-printing. | Tote Bag / Shopping Bag / Beach Bag / Storage Bag | 100% cotton, biodegradable; OEKO-TEX certified available. |

| Organic Cotton Canvas | GOTS-certified fiber, low-impact dyeing, premium eco appeal. | Sustainable Totes / Gift Bags | Certified organic; fully compostable. |

| Denim Canvas | Distinct weave, abrasion-resistant, fashion-forward. | Tote Bag / Backpack / Bucket Bag | Cotton-based, long-life cycle reduces waste. |

| Oxford Nylon (300D–600D) | Lightweight, waterproof, color-rich; resists tearing. | Travel Tote / Backpack / Duffel Bag | RPET versions available from recycled bottles. |

| Ripstop Nylon / Polyester | Grid-reinforced weave prevents tearing; strong yet soft. | Outdoor Tote / Crossbody Bag / Backpack | Available in recycled filament; fluorine-free coatings optional. |

| RPET (Recycled Polyester) | Made from post-consumer PET; strong, smooth, waterproof. | Eco Tote / Travel Bag / Storage Bag | GRS certified; reduces CO₂ and plastic waste. |

| Polyester Twill / Oxford | Affordable, wrinkle-resistant, holds color well. | Promotional Tote / Storage Bag | REACH compliant; recyclable fibers. |

| Tyvek® / Paper-like Fabric | Feather-light, tear-resistant, water-resistant with unique crinkle look. | Eco Tote / Gift Bag / Makeup Bag | 100% recyclable HDPE; PVC-free. |

| PU (Vegan Leather) | Looks and feels like leather, consistent grain, low cost. | Tote Bag / Handbag / Work Bag | Solvent-free / water-based PU available. |

| Microfiber PU Leather | Higher density, fine grain, soft handfeel, easy maintenance. | Premium Tote / Handbag | Long lifespan reduces replacement waste. |

| Genuine Leather (Cow / Goat / Sheepskin) | Natural grain, strength, luxury feel; develops patina. | Leather Tote / Satchel / Handbag / Wallet | Sourced from audited tanneries; vegetable-tanned options. |

| Split Leather / Bonded Leather | Economical leather option with uniform surface. | Work Tote / Corporate Gift Bag | Reuses leather fibers; low waste production. |

| Suede / Nubuck | Velvety touch, premium aesthetic. | Luxury Tote / Clutch Bag | Chrome-free tanning available. |

| PVC / TPU Film | Glossy, waterproof, ideal for clear or fashion totes. | Beach Bag / Travel Tote / Storage Bag | BPA-free PVC and recyclable TPU options. |

| Neoprene / SBR Rubber | Soft, flexible, shock-absorbing; sporty look. | Gym Tote / Laptop Bag / Beach Bag | Durable synthetic; recyclable SBR formulations. |

| Polyurethane Foam Laminates | Adds body and insulation; keeps shape. | Structured Tote / Lunch Bag | Non-toxic, CFC-free. |

| Jute / Hemp / Linen | Rustic texture, strong natural fibers, biodegradable. | Eco Tote / Beach Bag / Shopping Bag | Renewable crops; minimal water usage. |

| Raffia / Straw / Wicker | Lightweight, breathable, perfect for summer. | Beach Bag / Resort Bag / Clutch Bag | Plant-based; compostable. |

| Velvet / Corduroy / Chenille | Soft, tactile, luxurious appearance. | Evening Bag / Mini Tote / Clutch | Cotton or recycled-poly blend options. |

| Felt (Recycled PET or Wool) | Cushioned, structured, eco texture. | Laptop Tote / Storage Bag | Made from recycled fiber or wool offcuts. |

| Mesh / Net Fabric | Breathable, see-through, sporty aesthetic. | Beach Tote / Laundry Bag | RPET mesh available. |

| Quilted Fabric (PU or Nylon) | Padded 3-D texture, trendy design. | Fashion Tote / Shoulder Bag | Can use recycled filler; enhances insulation. |

| Waxed Canvas / Oilskin | Water-resistant, vintage appearance, long-lasting. | Outdoor Tote / Travel Bag | Re-waxable; plastic-free waterproofing. |

| Faux Fur / Sherpa | Warm, plush surface for seasonal capsules. | Winter Tote / Clutch Bag | Vegan; recyclable poly pile. |

| Knitted / Crochet Cotton | Artisanal aesthetic, flexible form. | Summer Tote / Beach Bag / Hobo Bag | 100% cotton; hand-made sustainable craft. |

We audit all fabrics to ensure transparent pricing and traceable quality.

Each batch of products is accompanied by material data sheets, MSDS safety data sheets, and colorfastness test reports, meeting compliance requirements for diverse clients and regions (EU REACH, US CPSIA, CA Prop 65).

Our sampling room keeps over 500 material swatches in stock, enabling immediate prototyping.

Designers can mix materials—e.g., canvas body with leather handles, or raffia panels framed in PU—to achieve hybrid aesthetics without losing structural integrity.

We regularly work with:

If you have a specific fabric in mind, we can evaluate it or source similar alternatives.

We usually suggest:

We’ll match fabrics to your use scenario, price range and brand positioning instead of forcing one default.

Fabric affects:

We’ll provide cost and MOQ ranges per fabric family and suggest where to use premium fabrics (hero SKUs) and where to use more economical options (core SKUs).

Yes—and it’s often a smart B2B strategy. With one fabric system you can build:

We’ll advise which fabrics can flex across types without performance issues.

Yes. We can:

We’ll help you find a balance between sustainability, performance and price.

We use fabric-specific QC, including:

This keeps your custom bag fabric performance stable across seasons and reorders.

Whether you need technical nylon backpacks, canvas shopper bags, PU fashion handbags, straw totes, or recycled-fabric eco lines, FYBagCustom helps you: