Tel/WhatsAapp:+86 13366396425

E-mail: chloe_xia@vleap.com.cn

For brands and travelers alike, understanding TSA approved quart size bag dimensions isn’t just a matter of compliance — it’s the intersection of safety, engineering, and consumer trust. The Transportation Security Administration (TSA) sets strict standards that influence how global manufacturers design, test, and deliver transparent toiletry bags for air travel.

This comprehensive guide is crafted for OEM and ODM manufacturers, procurement teams, and travel accessory brands that want to stay compliant while achieving market differentiation.

Compliance Note: Non-compliant toiletry bags can result in shipment rejections, customs delays, and potential liability if marketed as “TSA-approved” without verifiable specifications.

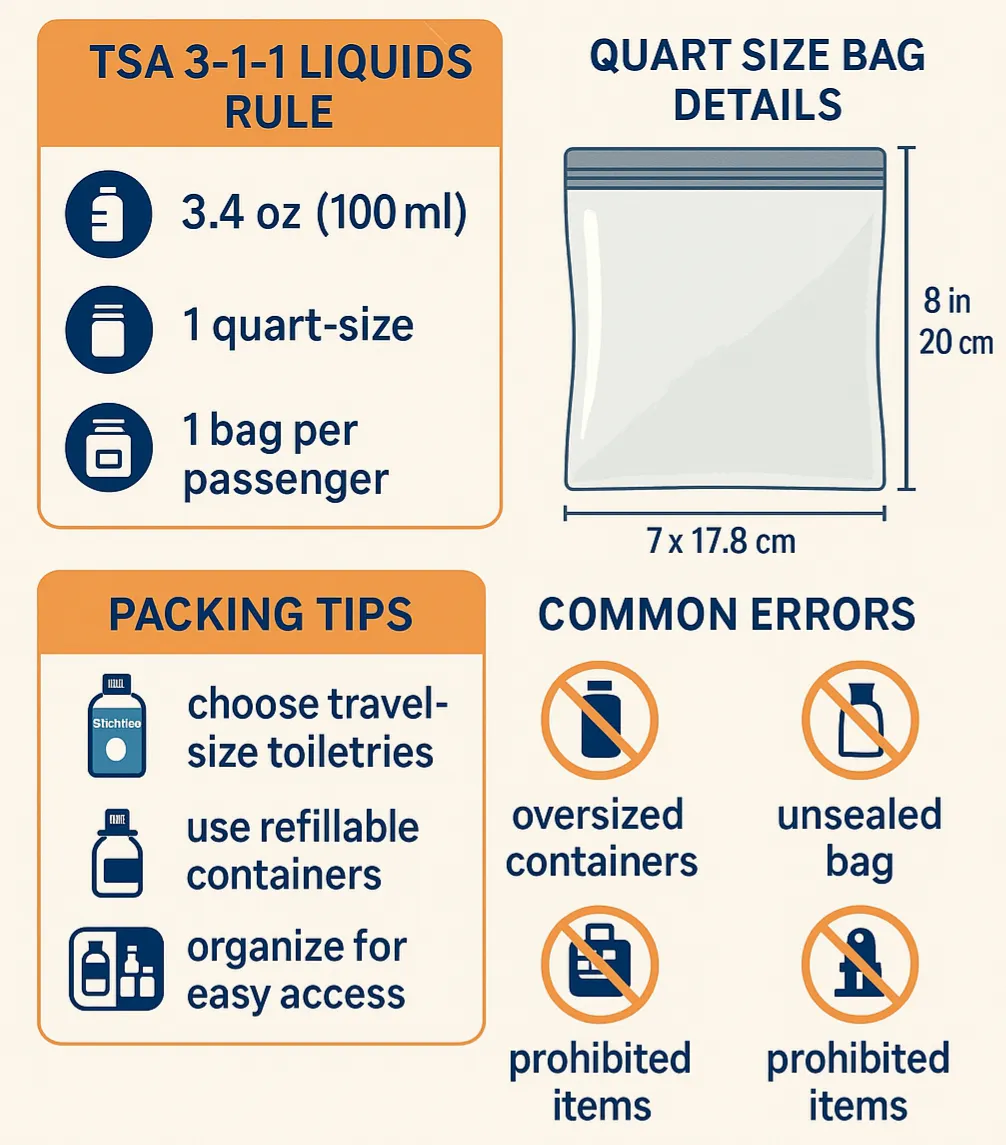

The TSA 3-1-1 liquids rule originated after the 2006 transatlantic liquid bomb plot, which led to international restrictions on liquid volumes allowed in carry-on luggage. “3-1-1” refers to:

Its goal is to limit the total volume of potentially hazardous substances passengers can bring aboard.

Manufacturers designing TSA-approved quart size bags must meet these material and dimensional criteria:

For OEMs, these rules define both product geometry and packaging constraints.

Designing around TSA guidelines ensures global usability — from American Airlines to British Airways, compliant products are accepted across most airports.

Design Tip: Keep the total volume below 1 L (946 mL) including the closure gusset. Excessive seam depth can cause the bag to exceed TSA’s perceived quart capacity.

| Measurement | Imperial | Metric |

| 1 Quart | 32 fl oz | 946 mL |

| 3.4 oz limit | 100 mL | 100 mL |

| Typical Bag | 7 × 8 in | 17.8 × 20.3 cm |

While TSA doesn’t certify individual products, staying within these figures ensures the bag qualifies as a “TSA-approved quart size bag.”

Compliance Note: Avoid opaque brand panels larger than 15 % of surface area; TSA officers may reject bags that obstruct visibility.

Different airlines interpret TSA compliance flexibly.

For instance:

Thus, designing within 17 × 19 cm ensures both US and EU compatibility.

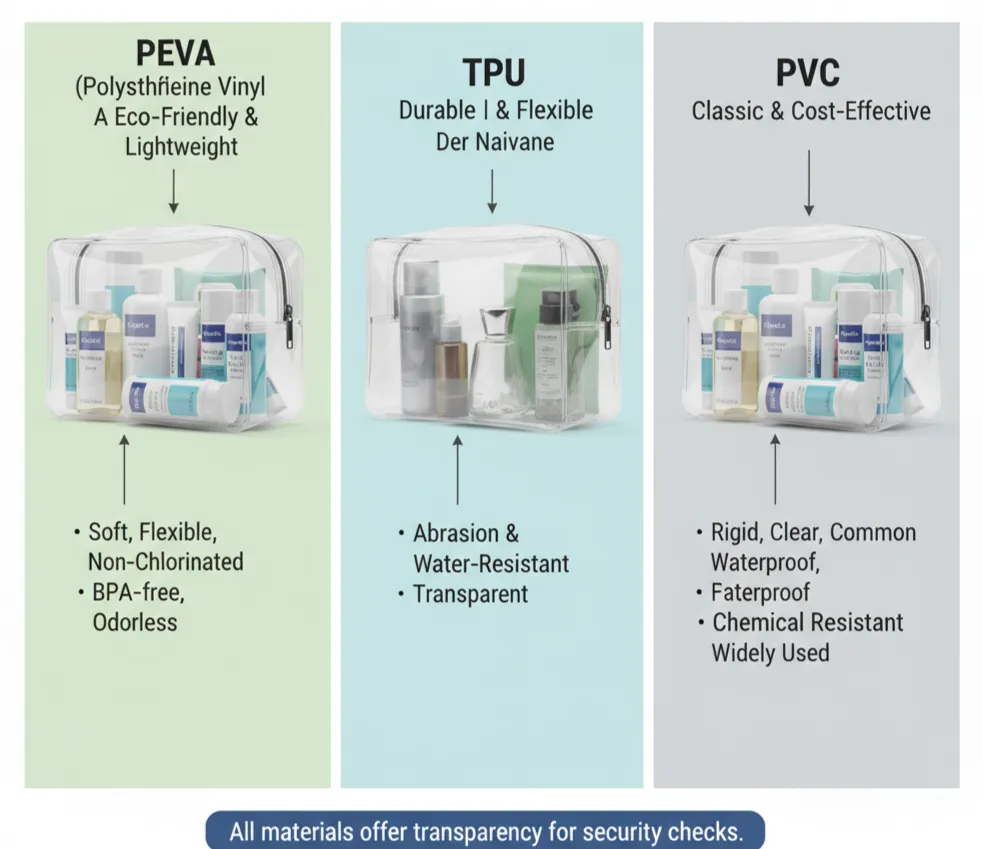

| Material | Transparency | Durability | Temperature Resistance | Eco Profile | Cost Level |

| PVC (Polyvinyl Chloride) | Excellent | High | −10 °C – 70 °C | Moderate (contains chlorine) | ★ |

| PEVA (Polyethylene-Vinyl Acetate) | Excellent | Medium | −15 °C – 80 °C | Good (chlorine-free) | ★★ |

| TPU (Thermoplastic Polyurethane) | Crystal Clear | Excellent | −30 °C – 90 °C | Excellent (biodegradable options) | ★★★ |

Material Insight:

FY recommends TPU for high-end cosmetic brands seeking long-lasting clarity and PEVA for brands prioritizing environmental positioning.

All exported toiletry bags should meet:

Failure to comply can lead to customs holds or forced recalls — especially when claiming “eco-friendly TSA-approved quart size bag”.

Compliance Note: FY’s production lines are audited under BSCI and ISO 9001, ensuring every shipment passes AQL 2.5/4.0 inspections.

For OEM/ODM toiletry bag manufacturers, the process begins with detailed CAD dimensional drafting.

Engineers simulate bag volume within 946 mL limits while optimizing structural rigidity.

Typical workflow:

Design Tip: Always verify the “filled geometry” — bags that appear smaller when empty may exceed 1 L when fully expanded, violating TSA quart-size definitions.

| Test Type | Standard | FY Reference |

| Transparency | ASTM D1003 | ≥ 85 % |

| Seal Strength | ASTM F88 | ≥ 10 N |

| Odor / VOC | ISO 16000 | Non-detectable |

| Cold Crack | ASTM D2136 | −25 °C |

| Aging Test | FY Lab #A-TPU-2025 | 100 hr @ 60 °C |

FY’s QC labs employ AQL 2.5/4.0, with 100 % inspection on critical functions (zip seal integrity, dimension tolerance, and clarity).

Compliance Note: Always include “Inspection Certificate” with shipment; many US importers now require documentation verifying quart-size compliance.

Proper labeling supports smooth customs clearance:

Design Tip: For Amazon FBA, keep outer carton under 25 kg and label with FNSKU; FY can print & apply per client request.

| Region | Limit per Container | Bag Volume | Remarks |

| USA (TSA) | 3.4 oz / 100 mL | 1 quart (≈946 mL) | “3-1-1 Rule” |

| EU / UK | 100 mL | 1 L | Similar to TSA |

| Canada (CATSA) | 100 mL | 1 L | Enforced strictly |

| Australia / NZ | 100 mL | 1 L | Must fit flat bag |

| Japan / Korea | 100 mL | 1 L | Often require resealable zip |

| China (CAAC) | 100 mL | 1 L | Domestic adoption of TSA rule |

Although rules are similar, interpretation varies:

Compliance Note: Always design packaging inserts in English + bilingual labels for EU/Asia to minimize misunderstanding at customs or security gates.

The EU has begun trialing CT-scanner systems allowing up to 2 L liquids by 2026.

FY are preparing “Next-Gen Clear Bag Designs” with enhanced RFID traceability for secure identification.

Effective packing not only ensures compliance but also demonstrates user-centric product design.

| Item | Recommended Size | Material | Tip |

| Shampoo / Conditioner | ≤ 3 oz (100 mL) | PE Bottle | Keep upright |

| Lotion / Cream | ≤ 3 oz | Soft Tube | Avoid excess air |

| Toothpaste | Travel size | Laminated Tube | Seal tightly |

| Perfume / Spray | ≤ 3 oz | Glass / Plastic | Use atomizer |

| Makeup Remover | ≤ 3 oz | Drop Bottle | Wrap in film |

Design Tip: Add internal gusset or divider to stabilize bottles during inspection handling.

| Airline | Carry-On Limit | Notes |

| American Airlines | 22 × 14 × 9 in | Liquids follow TSA 3-1-1 |

| Delta Air Lines | 22 × 14 × 9 in | Same standard |

| British Airways | 56 × 45 × 25 cm | EU 1 L rule |

| Air France / KLM | 55 × 35 × 25 cm | EU standard |

| ANA / JAL | 55 × 40 × 25 cm | Strict visual inspection |

Compliance Note: Design sample photos should clearly show dimensions on packaging artwork to reassure airline compliance officers.

FY Bag Custom Factory has over 15 years of manufacturing expertise in custom toiletry bags, clear pouches, and travel kits.

Our factory integrates R&D + production + QC + export—ensuring that every TSA approved quart size bag meets global standards.

Material Insight: FY supports sustainable transitions—introducing bio-based TPU and recycled PEVA programs by 2026.

Design Tip: FY’s in-house design team can adjust visual branding placement (<15 % opaque area) to maintain TSA transparency compliance.

Not exactly. Only those meeting size (~1 quart), transparency, and resealability standards will pass checkpoints.

Light tinting is often accepted, but opaque or patterned bags may be rejected.

Typically 3–5 years with proper care; TPU resists cracking and discoloration.

Use silk-screen or UV printing limited to <15 % coverage; FY ensures durability and ink compliance.

Yes. FY provides barcode printing, carton labeling, and shipment consolidation.