Tel/WhatsAapp:+86 13366396425

E-mail: chloe_xia@vleap.com.cn

Travel bags are typically purchased as “task-oriented combinations”: Carry + Organize + Quick Departure.

As a professional custom Travel & Vacation & Weekend Trips Bag solutions Manufacturer, FYbagcustom offers custom travel bags (and their derivatives) that excel in scenarios such as vacations, urban short trips, and weekend road trips:

Tell us your target look, material, quantity, and deadline. We’ll propose the right logo method, make a working sample, and ship retail- or FBA-ready products.

Travel silhouettes often fail on small details (zipper direction, strap drop, pocket placement). FY shorten iteration loops with 3–5 day sample development, then refine based on real packing tests.

Instead of “one logo option,” FY support travel-specific customization across: style, fabric, logo, hardware, packaging, shipping—so your launch plan and supply chain stay aligned.

Whether you bring a tech pack, a reference sample, or only a concept, FY support OEM/ODM development and scalable production for travel collections.

Travel bags face abrasion, load, and repeated handling. FY run full-process monitoring and 100% final inspection before shipment to reduce claim risk and review damage.

B2B positioning: premium “short-trip” hero SKU for capsule collections.

What buyers care about: capacity-to-silhouette ratio, strap comfort, zipper durability.

Typical engineering specs (common ranges):

Best channels: DTC travel brands, department store capsules, influencer drops.

B2B positioning: high-volume style that supports color/size variations for listings.

What buyers care about: organization, laptop safety, closure security.

Typical engineering specs:

Best channels: Amazon/Shopee sellers, chain retail programs, corporate gifting.

B2B positioning: versatile travel-sport crossover; strong for wholesale and bulk orders.

What buyers care about: structure stability, shoe compartment logic, heavy-load tolerance.

Typical engineering specs:

Best channels: sports retailers, promotional programs, clubs/teams.

B2B positioning: seasonal bestseller with fast turnover; great for resort retail and summer drops.

What buyers care about: sand release, drying speed, clean branding visibility.

Typical engineering specs:

Best channels: resort shops, cruise retail, seasonal e-commerce.

B2B positioning: the highest-repeat add-on in travel sets. Perfect for bundle SKUs and multi-pack variations.

What buyers care about: leak resistance, cleanability, visibility when opened.

Typical engineering specs:

Best channels: e-commerce bundle strategy, gift sets, retail add-on displays.

B2B positioning: turns “travel bag” into a system; increases bundle conversion and reduces returns due to better organization.

What buyers care about: sizing consistency, zipper glide, mesh breathability, set logic.

Typical engineering specs:

Best channels: marketplaces, wholesalers, chain retailers (bundle displays).

As a professional travel bag customization factory, FY collaborates with over 100 brands annually. We offer comprehensive production services for private-label travel bags and provide customization tailored to channel requirements. Our extensive customization options can meet all bespoke needs.

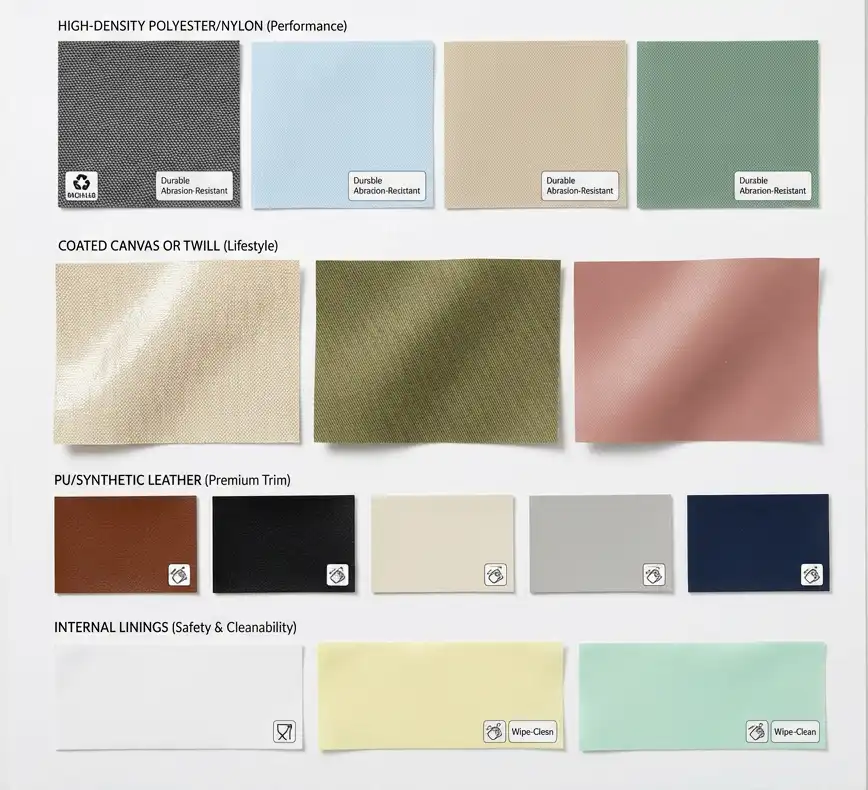

Choose based on positioning and claim risk:

Define 3 priority zones for your customer:

Options for OEM/ODM private label programs:

We recommend placements that avoid abrasion zones (edge corners, drag points, constant friction areas).

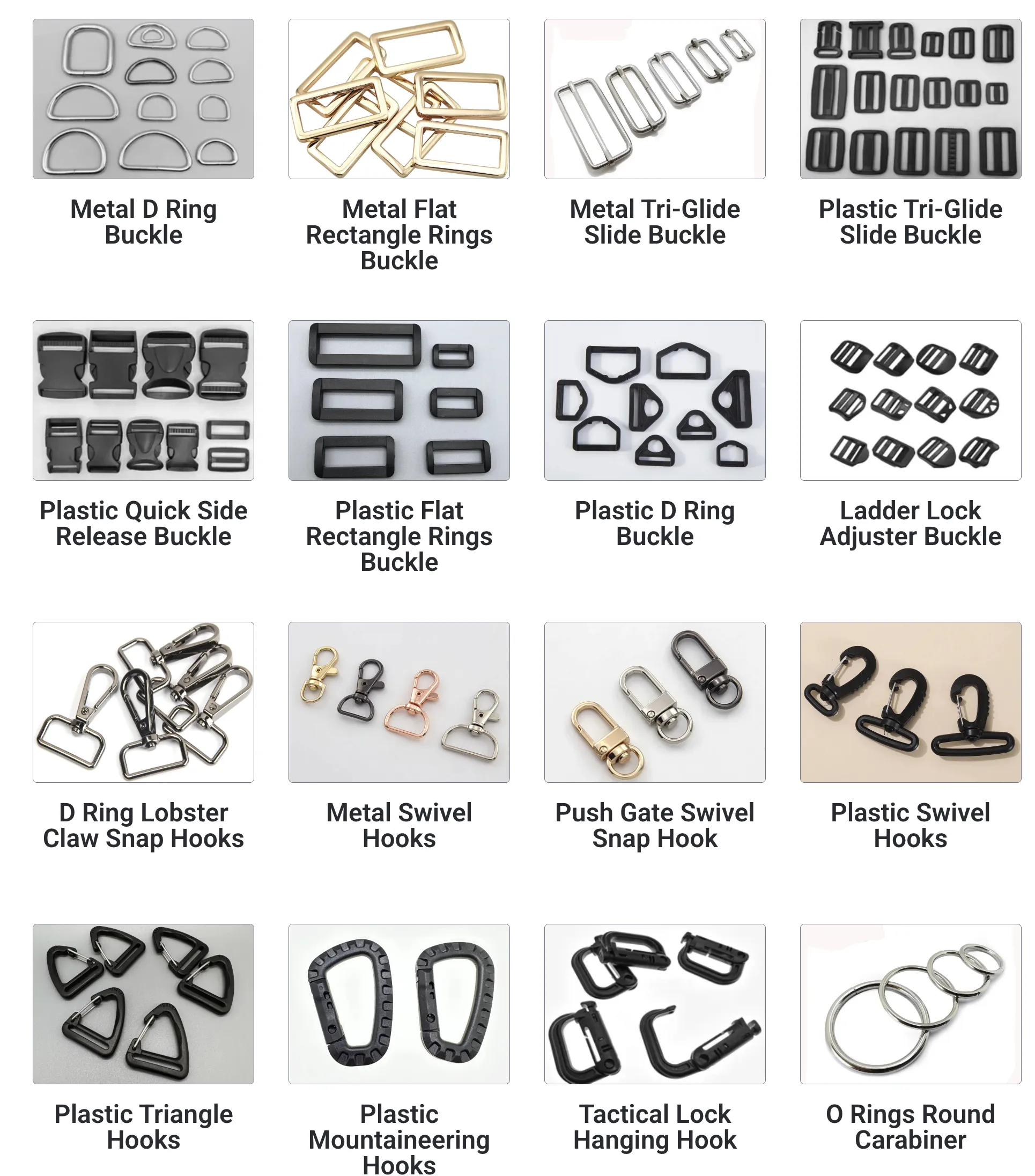

1.zipper gauge selection (#5/#8/#10)

2.hooks: metal vs high-strength plastic

3.buckles and adjusters matched for weight targets

1.dust bag / polybag / box sleeves

2.hangtags + barcode sets for chain retail and wholesale requirements

3.carton protection and labeling for export shipping

When sourcing from FY Custom Travel Bag Manufacturer (OEM/ODM) in China, material selection is not merely about aesthetics—it is essentially your warranty policy. FY provides a comprehensive material selection guide:

| Material Family (Outer) | Common Spec Range (What buyers ask for) | Key Advantages for Travel | Best-fit Travel SKUs | Watch-outs (Cost / QC) |

|---|---|---|---|---|

| Nylon Oxford | 210D–600D (often with PU/WR finish) | Balanced weight + durability; good for travel tote & weekender | Travel tote, weekender, toiletry kit | Coating consistency affects color + handfeel |

| High-Denier Nylon / Ballistic | 840D–1680D | Heavy-duty abrasion resistance; “premium rugged” positioning | Duffle, weekender base panels | Higher unit cost + stiffer drape |

| Nylon Ripstop | Lightweight ripstop grids | Strong for weight; great for packing cubes & sets | Packing cubes, laundry bags, shoe bags | Can feel “technical”; needs brand match |

| Polyester | 300D–900D | Cost-efficient; stable color; good for wholesale programs | Duffle, travel tote, storage sets | Some tiers abrade faster than nylon |

| Canvas (Cotton/Poly-cotton) | Mid to heavy canvas | Premium casual look; great for boutique travel lines | Travel tote, weekender | Higher weight; stain management needed |

| PU-coated fabric | PU coating + woven base | Better wipeability & light rain resistance | Toiletry/makeup bags, wet zones | Coating quality controls cracking risk |

| TPU laminated fabric | TPU film + textile base | Strong water barrier; premium performance feel | Toiletry bags, wet/dry pockets | Laminates require careful seam planning |

| Vegan leather (PU/Microfiber) | PU or microfiber leather | Luxury look; branding-friendly (deboss/emboss) | Travel tote, weekender accents | Heat/edge finishing system affects durability |

| Mesh (structured / soft) | Different mesh densities | Sand release + fast dry; perfect for resort use | Mesh beach tote, pocket panels | Branding placement needs abrasion planning |

Tell us your target look, material, quantity, and deadline. We’ll propose the right logo method, make a working sample, and ship retail- or FBA-ready products.

You send: target SKU family + reference + target quantity + market positioning.

We respond with: structure proposal + material plan + rough cost drivers.

Sample focuses on function points: zipper action, strap comfort, pocket usability, logo placement.

We lock: materials, trims, color standard, packaging spec, inspection checklist.

We monitor key processes and complete 100% final inspection before shipment.

Yes. We design the project as a system, standardizing materials, trims, logo methods, and packaging so the set looks coherent across SKUs.

Send

(1) target product family,

(2) reference images,

(3) order quantity,

(4) logo file + packaging requirement.

We will propose a structure plan and sampling route; typical sampling is 3–5 days.

In most travel programs, toiletry & makeup bags and packing cube sets reorder faster due to gifting and replacement demand, while the main bag drives higher ticket value.

We focus on engineering and inspection around the most common failure points: zippers, strap anchors, base reinforcement, wet/dry lining performance, plus 100% final inspection before shipment.

Yes. We can include hangtags, barcode labeling, dust bags, and export cartons to match retail and marketplace requirements.

A practical weekender usually targets the 30–45L range, balancing “fits enough” with a silhouette that still looks premium on-body. For OEM programs, we recommend confirming size using packing tests (shoes + toiletries + 2 outfits) before locking the pattern. As an OEM/ODM travel bag factory, we can prototype size adjustments during sampling to prevent returns caused by “smaller than expected” complaints.

For most travel use:

It depends on your positioning:

Ready to build a private label travel bag system that sells in bundles?

Send your target SKU list (weekender/tote/duffle + toiletry/makeup + packing cubes/storage) and quantity. We’ll return a sampling plan + cost structure for your travel program.